Level up Your Safety!

SX6 safety module

A new level of safety.

With its 6th generation of drive controllers, STOBER offers innovative solutions for the increasing requirements in automation and mechanical engineering. The SX6 safety module is a brand new addition to the portfolio. It adds numerous safety functions to the range of functions of SB6, SC6 and SI6 drive controllers. It is controlled via EtherCAT® (Fail Safe over EtherCAT, FSoE).

Many ways to achieve machine safety.

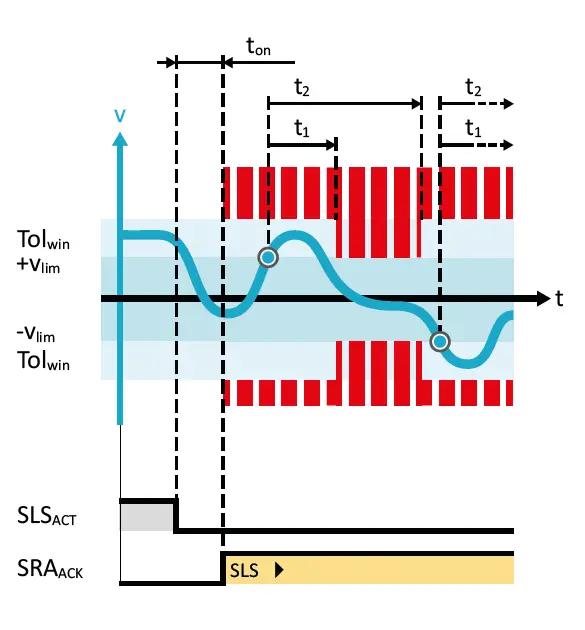

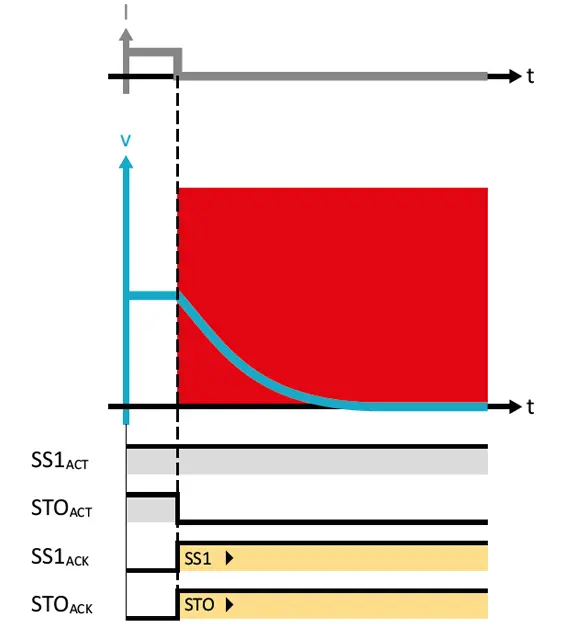

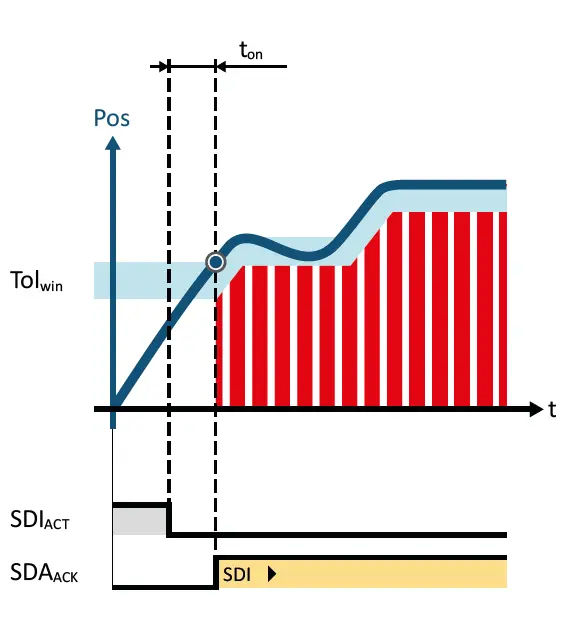

The SX6 enables the conventional Safe Torque Off (STO), Safe Stop 1 (SS1) and Safe Stop 2 (SS2) stop functions. A special highlight is that the STO function can be activated individually for each axis on multi-axis controllers. In addition, Safely-Limited Speed (SLS) and Safe Speed Range (SSR) ensure that the projected velocity limits are always adhered to. Safe Direction (SDI) monitors the direction of motion, while Safely-Limited Increment (SLI) limits the increment and Safe Operating Stop (SOS) ensures a safe standstill.

Brake management:

Protection against falling axes.

Gravity-loaded axes can drop uncontrollably due to wear or contaminated brakes and thus pose a considerable risk. For this application, STOBER is expanding the SX6 with a powerful brake management system that meets the requirements of German Social Accident Insurance (Deutsche Gesetzliche Unfallversicherung – DGUV) for such axes.

At its core are two functions: Safe Brake Control (SBC) ensures that the brakes are applied safely. Safe Brake Test (SBT) checks the specified braking torque at defined intervals as needed, detects deviations at an early stage, and uncovers possible defects – before the braking torque reaches a critical state. Since the brake management system supports control of up to two brakes, it covers all the applications specified in the DGUV Division Information Sheet on gravity-loaded axes.

The benefits at a glance.

- FsoE Certified Product.

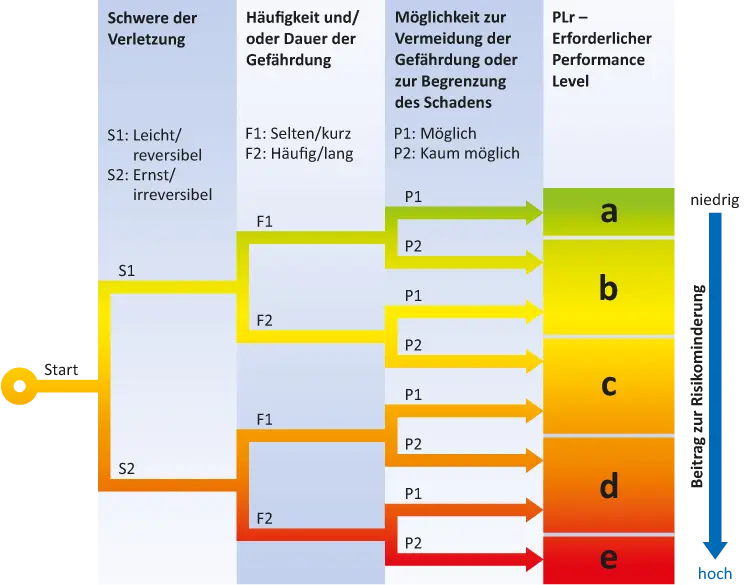

- Extended safety functions up to SIL 3, PL e, category 4.

- Safe brake management for standard-compliant protection of gravity-loaded axes.

- Compatible with SB6, SC6 and SI6 drive controllers.

- No safety encoder necessary.

- Free selection of motors and cables.

- Elimination of standstill or speed monitors.

- Straightforward project configuration and commissioning.

- Simple, quick service concept.

We would be happy to give you advice.

Please contact us.

„To increase productivity and availability, we have extended the monitoring mechanisms beyond the basic standardized requirements. Position-based limit value monitoring and predictive suppression of interference signals enable the intended limit values to be approached with a minimal interference distance..“

– Matthias Meyering, Technical Product Manager, STOBER

The benefits

This might also interest you

6th Generation Drive Controllers

Whether for high-performance systems, highly efficient multi-axis applications or compact modules – the 6th generation from STOBER always has the right drive controller on hand.

Play it safe with STOBER safety technology: Benefit from economical solutions with maximum safety, a wide range of functions and absolute flexibility.

Energy efficiency is highly relevant in drive technology. STOBER experts advise on the dimensioning of an entire drive train.

Connected at a distance: The new STOBER hybrid cable reliably connects motors and drive controllers at 100 meters.