Whitepaper

Safety

1. Executive Summary

These days, safety functions are an integral part of modern drive systems. Conventional safety architectures with external control are often considered inflexible and complex to integrate. With the SX6 safety module, relevant safety functions can be integrated directly into the 6th generation SC6 and SI6 drive controllers – without separate monitoring components such as speed monitors. This reduces the wiring effort and enables shorter response times and smaller protective distances – while at the same time ensuring high system availability.

This white paper explains how the SX6 implements safety functions with safety certifications (SIL 3, PL e, Category 4).

2. Introduction: Safety as an integral part of modern drive technology

New standards such as DIN EN ISO 13849-1 and EN 61800-5-2 place high demands on the functional safety of modern machines and systems. At the same time, the need for flexibility and availability is increasing – these days, safety functions must be able to be integrated smoothly into highly dynamic production processes.

The key challenge is to reconcile efficiency, adaptability and safety – without compromising productivity. That demands end-to-end safety solutions that are easy to integrate and guarantee minimum downtime and maximum operational reliability – even in complex multi-axis applications.

This is where STOBER comes in with the SX6: a safety module that is integrated directly into the SC6 (stand-alone) and SI6 (multi-axis drive system with central supply module) drive controllers. The safety functionality thus becomes an integral part of the drive architecture, making additional external monitoring mechanisms unnecessary.

3. Presenting the SX6 safety module: Developed for 6th generation drive controllers

The SX6 extends the 6th generation drive controllers – SC6, SI6 and, since the end of 2025, the SB6 – with numerous certified safety functions up to SIL 3, PL e (Category 4). STOBER developed this module together with Pilz GmbH & Co. The focus has always been on practicality. In order to increase productivity and machine availability, STOBER has supplemented the monitoring mechanisms of the safety functions beyond the basic normative requirements. Position-based limit value monitoring and predictive interference signal suppression enable limit values to be approached precisely with minimal interference distance. With its consistent two-channel structure, the SX6 tests the safety-related components every time the device starts up, after each execution of Safe Torque Off (STO) and during operation. This eliminates the need for end customers to perform cyclical checks of the safety functions, which must be documented.

STOBER has also optimized the switch-off channels of the STO and Safe Stop 1 (SS1) stop functions: At just five and six milliseconds, respectively, they work significantly faster. These low worst case response times, minimized safety distances, and, above all, rapid availability significantly reduce system outages and downtime.

“To increase productivity and availability, we have expanded the monitoring mechanisms beyond the basic normative requirements. Position-based limit value monitoring and predictive suppression of interference signals enable the target limit values to be approached with minimal interference distance.”

– Tim Lang, Head of Applications, STOBER

The SX6 is controlled via EtherCAT using the safe protocol FailSafe over EtherCAT (FSoE). As the existing EtherCAT infrastructure is used, the cabling effort is significantly reduced. Safe communication is based on a black channel principle and is transmitted together with functional EtherCAT communication via the same connection. What’s more, the SC6 and SI6 series drive controllers have successfully passed the EtherCAT and FSoE conformance tests. In particular, the communication interface has been tested to ensure reliable and manufacturer-independent functionality of the safety-related data transmission.

Safety functions (according to EN 61800-5-2)

The SX6 enables the classic stop functions STO, SS1 and Safe Stop 2 (SS2). With multi-axis controllers, the STO safety function can be activated individually for each axis. In addition, Safely Limited Speed (SLS) and Safe Speed Range (SSR) ensure that the drive does not exceed the configured speed limits. Safe Direction (SDI) controls the configured direction of motion, while Safely Limited Increment (SLI) reliably limits the increment of an axis movement. The Safe Operating Stop (SOS) function ensures a safe stop while the torque remains active.

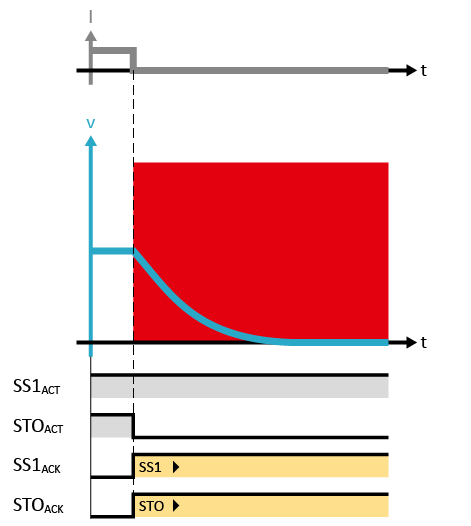

STO – Safe Torque Off

No energy is supplied to the motor that could cause rotation (or motion in the case of a linear motor). The PDS(SR) electric Power Drive System does not supply the motor with energy that can generate torque (or, in the case of a linear motor, force).

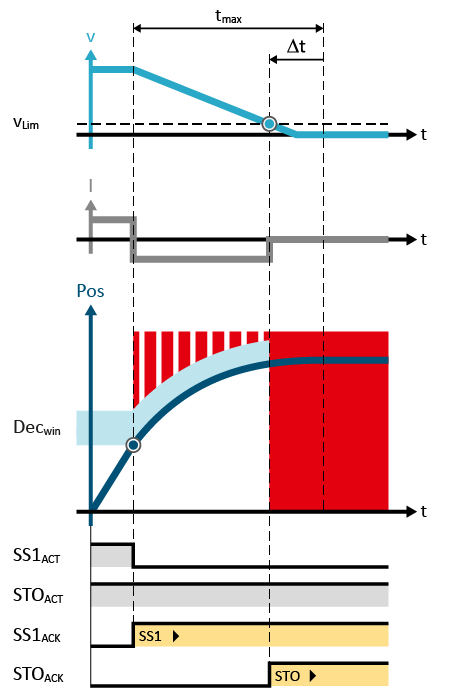

SS1 – Safe Stop 1

Safe stop with controlled braking: The SS1 safety function enables a controlled stop of the motor. The STO safety function is then executed, and the motor is brought into a torque-free/force-free state.

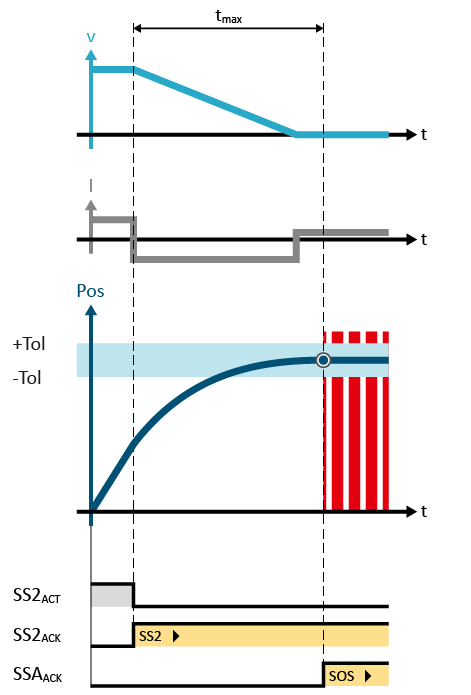

SS2 – Safe Stop 2

Safe stop with torque maintenance. The SS2 safety function enables the motor to be stopped in a controlled manner. The motor is then monitored for safe standstill (SOS) – for example for the holding function with vertical axes.

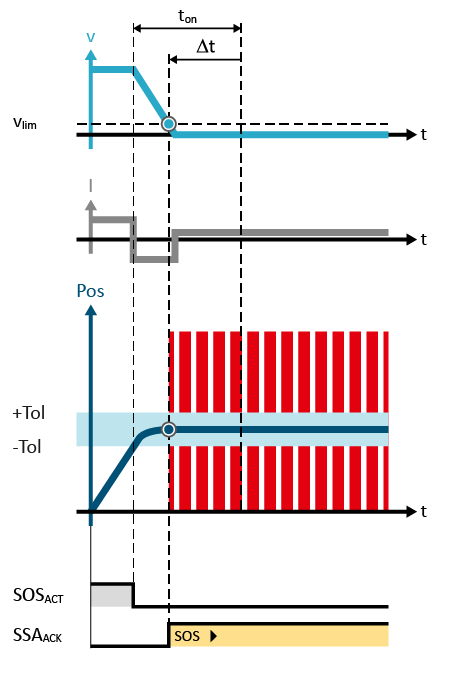

SOS – Safe Operating Stop

The SOS safety function prevents the motor from deviating from the holding position by more than a specified amount. The PDS(SR) electric Power Drive System supplies the motor with the energy it needs to withstand external forces.

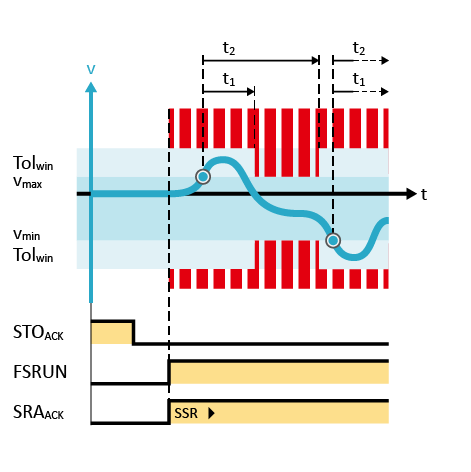

SLS – Safely Limited Speed

The SLS safety function prevents the motor from exceeding the specified speed limit.

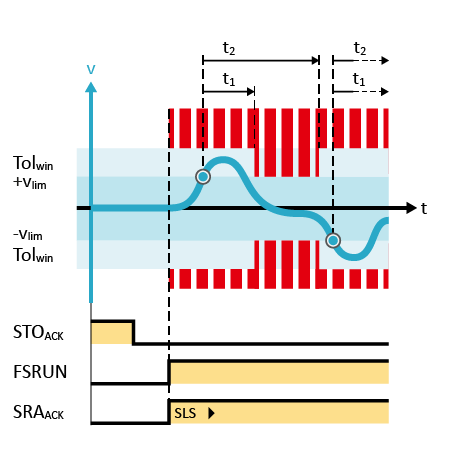

SSR – Safe Speed Range

The SSR safety function keeps the motor speed within defined limits.

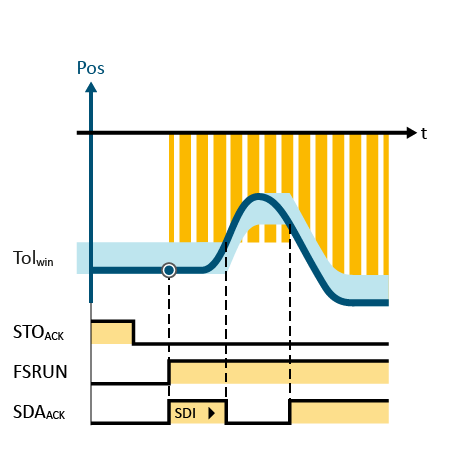

SDI – Safe Direction

The SDI safety function prevents the motor shaft from moving in an unintended direction.

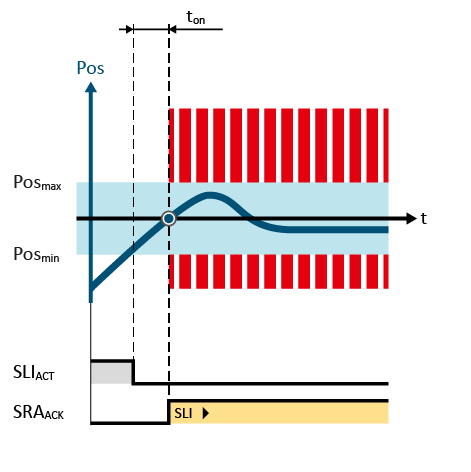

SLI – Safely Limited Increment

The SLI safety function prevents the motor shaft from exceeding the specified limit of a positional increment.

STOBER supplements the safety functionality with predictive mechanisms:

- Position-based limit value monitoring

- Suppression of interference signals for precise state changes

- Self-tests every time the device is started, after STO and during operation

- Monitoring functions

- Fallback level SS1! Controlled shutdown is smarter than switch-off – and faster

- Safe brake management

This reduces not only the maintenance effort but also end customer tests that require documentation.

4. Advantages of the SX6 in industrial use:

Manufacturer-neutral interfaces, simple service concept

No special motors, encoders, cables, standstill monitors or speed monitors are required in order to operate the safety module. Design engineers can continue to use existing drive configurations or switch to the components used in the application. This usually reduces system costs. In case of service, an existing safety configuration can be transferred quickly and easily to other drive controllers using an SD card for data storage. No special knowledge or software tools are required for this.

5. New Machinery Regulation: Greater responsibility for functional safety

As of January 20, 2027, the new European Machinery Regulation (EU) 2023/1230 will replace the previous Machinery Directive 2006/42/EC – and will bring with it far-reaching changes. In addition to being directly applicable in all member states, it significantly expands the scope of application: Digital components such as safety-relevant software, AI-supported control systems and networked systems will also be subject to binding requirements. Machine manufacturers therefore have a responsibility to manage risks not only through mechanical means, but also increasingly also through function and digital means.

For drive technology, this means that safety must be deeply integrated into the systems and guaranteed throughout the entire life cycle. State-of-the-art modules such as the SX6 make a decisive contribution to this. They make it possible to monitor motions precisely, bring machines into safe states in a targeted manner and, at the same time, react flexibly to changing requirements – for example in modular production systems or for manual interventions during operation.

6. Typical application scenarios

The SX6 functionality is suitable for applications with high dynamics and short cycle times in various industries:

- Robot technology and handling systems

Precise axis locking even with high movement dynamics. - Packaging machines

Reliable format changeover without reset at high cycle rates. - Machine tools

High process reliability thanks to short reaction times and small safety distances. - Plastics processing

Efficient protection of multi-axis machines thanks to fast response times.

Possible special application – conveyor technology: controlled standstill and safe restart – also in passenger transportation

7. Safety functions – implementation in real life

STOBER customers whose machines are already equipped with conventional safety technology are currently intensively testing the SX6 with extended safety technology – in particular, they are putting reliable monitoring of motions and targeted drive shutdown to the test across many different industries. The focus is not only on compliance with applicable standards, but also on alignment with the forthcoming EU Machinery Regulation well in advance.

Speed control for passenger transport with AGVs

Automated Guided Vehicles (AGVs) are also increasingly being used in applications where people are transported – for example in amusement parks. Particularly strict functional safety requirements apply in such scenarios. Speed monitoring plays an especially important role in effectively preventing hazards caused by uncontrolled motions or collisions.

The SLS safety function guarantees that specified maximum speeds are not exceeded. If necessary, a reaction, such as braking with subsequent safe standstill, is triggered automatically. In addition, the SSR-M (Safe Speed Range – Monitoring) function monitors how the AGV moves within a predefined speed range. If it leaves this zone, a warning is issued – even before a risk arises.

Safe and controlled commissioning

Precise and safe procedures are essential when commissioning large machines, such as those used in stone processing. A manufacturer of bridge saws for large-format stone slabs uses multiple drivetrains to implement motion sequences, including linear travel, turning, lifting and lowering. The complex commissioning of these machines is made easier for end customers – thanks to the SLS safety function integrated into the SX6. It enables a targeted reduction in speed during setup and configuration, especially when the safety gate is open. This increases safety for the operating personnel and, at the same time, allows convenient, controlled commissioning.

Operator protection with maximum productivity

Fast, smooth processes are essential in highly automated stamping and forming technology. At the same time, the protection of operating personnel must not be neglected – especially when machines are designed to be open to facilitate handling.

Therefore, a manufacturer of coil unwinders specifically relies on several safety functions within the STOBER drive system:

- STO for immediate torque cut-off

- SS1 for controlled braking

- SLS for limiting the unwinding speed

- SDI to ensure a fixed direction of motion

In this way, a high level of operator safety can be reliably combined with maximum productivity, even at high process speeds.

Safety in plastics processing: Eugen Riexinger GmbH & Co. KG

Fast, precise and safe movements play a central role in the automated processing of plastics. That’s why a long-standing customer from the special machine construction sector relies on state-of-the-art drive technology with integrated safety from STOBER for its welding, milling and sawing systems.

In the current project – a complex automation solution with over 40 axes and a wide range of functions – the safety functions of the new SX6 module are used alongside drive and control technology. Besides the usual STO and SS1 safety functions, the SLS function allows safe slow motions. This means that slow motions can be realized with the axes, which are otherwise fast and very dynamic, without endangering the operator – for example during loading or maintenance work.

In addition, SLS is increasingly being used to continue the process without interruption when the operator intervenes, for example with force-guided welding processes or axes under load.

Realization of extended safety logic

Safety functions also play a central role in complex processing machines for wooden panels. In these large-format systems, operators sometimes have to remain in the machine’s danger zone during maintenance or commissioning work. Therefore, conventional safety functions such as STO or SS1 alone are often not sufficient and must be supplemented by additional safety mechanisms.

For example, integrated logic can detect tool misalignments or blockages. If a safety-critical area is violated, the connected system reacts immediately and switches off – to protect people and machines. The modular architecture of the SX6 safety module enables flexible integration of all safety-relevant functions into existing control concepts.

8. Conclusion & outlook

STOBER supports mechanical engineers with design and commissioning – including practical tools for safety parameterization and the associated supporting documentation. With the SX6, STOBER integrates safety functions directly into the drive technology. This reduces components, simplifies the machine architecture and shortens response times. The result: greater flexibility, less wiring, shorter downtimes.

An overview of the benefits:

- FsoE certified product

- Extended safety functions up to SIL 3, PL e (Category 4)

- Compatible with SC6 and SI6 drive controllers

- Without additional safety encoder

- Free choice of motors and cables

- Eliminates need for standstill monitors or speed monitors

- Straightforward project configuration and commissioning

- Simple, fast service concept

- Optimal preparation for forward-looking concepts such as digital twins, edge safety and Industry 4.0

- Safety without additional components: No special motors, encoders, speed monitors or standstill monitoring required

- Minimal cabling effort: FailSafe over EtherCAT ensures smooth communication

- Extremely fast reaction times: STO < 5 ms, SS1 < 6 ms – for minimum safety distances

- Rapid recovery of availability: Quick reset without lengthy system tests

- High system efficiency: reduced downtime thanks to intelligent safety architecture

- Simple project transfer: Safety project configuration can be transferred to other drive controllers via SD card. This also supports fast service

The combination of safety-oriented functionality and powerful drive technology makes the SX6 an important technical element for the implementation of safe, intelligent machine architectures.

9. Appendix

| Feature | Value |

|---|---|

| Safety level | SIL 3, PL e (Category 4) |

| Safety functions | STO, SS1, SS2, SLS, SSR, SDI, SLI, SOS |

| Compatible drive controllers | SC6 (stand-alone), SI6 (multi-axis), SB6 coming soon |

| Communication | FailSafe over EtherCAT (FSoE) |

| Reaction times | STO: 5 ms, SS1: 6 ms |

| Project transfer | SD card (safety project migration) |

| Test cycles | Automatically at every start/stop/operation |

| Certifications & standards • DIN EN ISO 13849-1 • EN 61800-5-2 • IEC 61508 | |

Contact

STÖBER Antriebstechnik GmbH + Co. KG